Hardware & Supply Product Gallery

10143 Male NPT 43 Series Parker Crimp Fitting

- Material: Steel

- Trade Name: Parkrimp

- Series: 43

- Configuration Type: Male NPTF Pipe - Rigid - Straight

- Inch/Metric: Inch

- Parker Division: Hose Products

- Parker Group: Fluid Connector

- Inner Diameter Inch/mm: Inch

- End 1 Type: Inch

- Hose Connection Type: Permanent

- Fitting End: Male

- Fitting Type: NPTF Pipe

- Fitting Movement: Rigid

- Fitting Shape: Straight

- Fitting Connection: Crimp

Lawson Tru-Torq® Hex Cap Screw Grade 9 Alloy Steel 3/8-16 x 1/2

Ultra-high-strength matched component fastening system

• 20% stronger than Grade 8

• Fatigue/vibration-resistant UNJ thread design

• 20% higher-than-normal wrenching surface for increased safety and even distribution of torque forces

• Heat-treated, quenched and tempered

• Perma Plated for superior corrosion protection

• Proprietary head marking for improved traceability

• Diameter marked on head for easy identification

• Trailing thread does not enter the extrusion angle

• Increased length of chamfer allows easier alignment and assembly

• Matched strength nuts, flat washers and lock nuts available

• Minimum 180,000 PSI tensile strength

• Exceeds SAE, ASTM and Military Grade 8 strength requirements

• Designed for the most demanding maintenance requirements

• For use in critical applications

Minimum Threaded Length – Up to 6" Long: (2 x Diameter) + 1/4"; Over 6" Long: (2 x Diameter) + 1/2

(UCF-204-12) EBC 3/4" Flange Block Ball Bearing (4 Hole)

- Bearing Insert Type: Ball

- Bore Dia.: 3/4 in

- Shaft Locking Type: Set Screws

- Bearing Housing Material Type: Cast Iron

- Bearing Insert Material: 52100 Chrome Steel

- Bolt Hole Center-to-Center: 64 mm

- Series: UCF

- Bolt Size: 3/8 in

- Overall Height: 33.3 mm

- Locking Type: Set Screw

- Standards: AFBMA, ISO

- Overall Width: 86 mm

- Item: 4 Bolt Flange Bearing

- Dynamic Load Capacity: 2,877 lb

- Finish: Painted

- Bearing Lubrication: Shell Alvania RL2 or NLGI #2 Equivalent

- Temp. Range: -40 Degrees to 250 Degrees F

- Housing Material: Cast iron

- Overall Length: 86 mm

- Static Load Capacity: 1,494 lb

- Seal Material: Rubber

- Housing Type: Square

- Lubricant Material: NLGI #2 Equivalent

- System of Measurement: Inch

- Static Radial Load Capacity: 1,494.98 lbf

- Lubrication Openings: One Zirc Fitting

- Number of Mount Holes: 4

- Rolling Element Rows: 1

- Flange Thickness: 0.468 in

- Features: Anti-Rotation Device, Cast-Iron Housing, Dual Heavy-Duty Slinger Type Contact Seals, Standard Duty Square Flange Unit, Set Screw Locking, Triple Lip Seals (R3 Suffix) Optional, Wide Inner Ring Bearing

- Maximum Temperature: 250 Degrees F

- Included Bearing: UC204-12

- Mount Hole Center-to-Center Length: 2.531 in

- Minimum Temperature: -40 Degrees F

- Bearing Material Grade: 52100

- Mount Hole Size: 15/32 in

- Closure: Double Sealed

- Mount Hole Center-to-Center Height: 2.531 in

- Bore Type: Cylindrical

- Mounting Bolt Size: 3/8 in

- Housing Material Finish: Painted

- Bore Diameter: 3/4 in

(UCF 206-18) EBC 1-1/8" Flange Block Ball Bearing (4 Hole)

- Bore Size: 1-1/8"

- Bearing Number: UC206-18

- Housing Number: F206

- Number of Bolts: 4

- Bolt Size: 3/8 in

- Bearing Inner Diameter: Metric 28.575 mm

- Bearing Inner Diameter: Inch 1 1/8 in

- Bearing Width Inner Ring: (Bi) Matric 38.10 mm

- Bearing Width Inner Ring: (Bi) Inch 1.50 in

- Bolt Hole Center to Center: Matric 83 mm

- Bolt Hole Center to Center: Inch 3.267 in

- Flange width: Matric 108 mm

- Flange width: Inch 4.251 in

- Overall Height: Matric 40.2 mm

- Overall Height: Inch 1.582 in

- Dynamic Load Rating: Cr 19500 N

- Static Load Rating Cor: 11200 N

- Limiting Speed: 6300 r/min

- Clearance: Normal

- Bearing Closures: Two Metal Shields (ZZ)

- Lubrication Type Grease: Shell RL2

- Lubrication Temperature: -20°C to +160°C

- Rolling Element Indicator: Ball

- Bearing Material: Gcr15

- Housing Material: H2000 Cast Iron

- Locking Type: Set Screws

- Product Weight: 1.00 KG

(UCF 207-22) EBC 1-3/8" Flange Block Ball Bearing (4 Hole)

- Item: UCF207-22

- Series: UCF200

- Bore Size: 1-3/8"

- Bearing Number: UC207-22

- Housing Number: F207

- Number of Bolts: 4 Bolt Size (S) 7/16 in

- Bearing Inner Diameter: Metric 34.925 mm

- Bearing Inner Diameter: Inch 1 3/8 in

- Bearing Width Inner Ring: (Bi) Matric 42.9 mm

- Bearing Width Inner Ring: (Bi) Inch 1.688 in

- Bolt Hole Center to Center: Matric 92 mm

- Bolt Hole Center to Center: Inch 3.622 in

- Flange width: Matric 117 mm

- Flange width: Inch 4.60 in

- Overall Height: Matric 44.4 mm

- Overall Height: Inch 1.748 in

- Dynamic Load Rating: Cr 25500 N

- Static Load Rating: Cor 15300 N

- Limiting Speed: 5300 r/min

- Clearance: Normal

- Bearing Closures: Two Metal Shields (ZZ)

- Lubrication Type: Grease Shell RL2

- Lubrication Temperature: -20°C to +160°C

- Rolling Element Indicator: Ball

- Bearing Material: Gcr15

- Housing Material: H2000 Cast Iron

- Locking Type: Set Screws

- Product Weight: 1.230 KG

(UCP 211-35) EBC 2-3/16" Pillow Block (2 Hole)

- Bearing Insert Type: Ball

- Bore Dia.: 1 3/16 in

- Shaft Locking Type: Set Screws

- Bearing Housing Material Type: Cast Iron

- Bearing Insert Material: 52100 Chrome Steel

- Bolt Hole Center-to-Center: 4 5/8 in

- Mounting Surface to Shaft Center: 1 11/16 in

- Series: Standard Duty

- Number of Bolts: 2

- Dimension L: 6 1/2 in

- Dimension A: 1 7/8 in

- Dimension J: 4 5/8 in

- Dimension H: 1 11/16 in

- Dimension B: 1 1/2 in

- Bolt Size: 1/2 in

- Dimension H1: 21/32 in

- Dimension N: 9/16 in

- Bearing Lubrication: Shell Alvania #3 or NLGI #3 Equivalent

- Dimension H2: 3 9/32 in

- Overall Length: 6 1/2 in

- Temp. Range: -20 Degrees to 250 Degrees F

- Dynamic Load Capacity: 4,400 lb

- Locking Type: Set Screw

- Dimension D: 1 3/16 in

- Item: Pillow Block Bearing

- Dimension S: 5/8 in

- Finish: Painted

- Static Load Capacity: 2,540 lb

- Overall Height: 3 9/32 in

- Housing Material: Cast iron

- Overall Width: 1 7/8 in

- Number of Mount Holes: 2

- Inner Ring Width: 1.5 in

- Housing Material Finish: Black Oxide

- Dynamic Radial Load Capacity: 4,384 lbf

- Mount Hole Size: 0.563 in x 0.937 in

- Lubricant Material: NLGI #3 Equivalent

- Base Width: 1.874 in

- Center Height: 1.688 in

- Mounting Bolt Size: 1/2 in

- Static Radial Load Capacity: 2,540 lbf

- Seal Type: Contact

- Mount Type: Bolt-Through

- System of Measurement: Inch

- Minimum Temperature: -40 Degrees F

- Mount Hole Center-to-Center Length: 4.626 in

- Closure: Open

- Maximum Speed: 5,900 RPM

- Bore Diameter: 1 3/16 in

- Bore Type: Cylindrical

- Seal Material: Nitrile Rubber

- Features: Light Duty

- Bearing Material Grade: 52100

- Base Height: 0.657 in

- Maximum Temperature: 250 Degrees F

- Country of Origin (subject to change): Japan

(UCF 205-14) 7/8" Flange Block Ball Bearing (4 Bolt)

(UCF 205-16) EBC 1" Flange Block Ball (4 Hole)

- Manufacturer Name

- EBC

- Weight / Kilogram

- 0.861

- Number of Mounting Holes

- 4

- Mounting Method

- Set Screw

- Housing Style

- 4 Bolt Square Flange Block

- Rolling Element

- Ball Bearing

- Housing Material

- Cast Iron

- Expansion / Non-expansion

- Non-Expansion

- Mounting Bolts

- 3/8 Inch

- Relubricatable

- Yes

- Insert Part Number

- UC205-16

- Seals

- B Seal

- Housing Configuration

- 1 Piece Solid

- Pilot Configuration

- No Pilot

- Inch - Metric

- Inch

- Other Features

- Single Row | Spherical | Gray Epoxy Paint Finish

- Category - BDI

- Flange Block

- UNSPSC

- 31171501

- Harmonized Tariff Code

- 8483.20.40.40

- Noun

- Bearing

- Keyword String

- Flanged

- Manufacturer Item Number

- UCF 205

- Weight / LBS

- 1.9

- Long Description

- 4 Bolt Square Flange Block; 1" Bore; 4" Bolt Circle; 2-3/4" Bolt Spacing; 1 Piece Solid; Set Screw Mount; Cast Iron; Ball Bearing; 1-11/32" Length Thru Bore; Relubricatable; B Seal Seals

- Nominal Bolt Circle Diameter Round

- 4 Inch | 101.6 Millimeter

- Bore

- 1 Inch | 25.4 Millimeter

- Length Thru Bore

- 1.343 Inch | 34.1 Millimeter

- Bolt Spacing

- 2.75 Inch | 69.85 Millimeter

(UCF 207-23) EBC 1-7/16" Flange Block Ball Bearing (4 Hole)

- Bearing Number: UC207-23

- Housing Number: F207

- Number of Bolts: 4

- Bolt Size: 7/16 in

- Bearing Inner Diameter Metric: 36.513 mm

- Bearing Inner Diameter Inch: 1 7/16 in

- Bearing Width Inner Ring Matric: 42.9 mm

- Bearing Width Inner Ring Inch: 1.688 in

- Bolt Hole Center to Center Matric: 92 mm

- Bolt Hole Center to Center Inch: 3.622 in

- Flange width Matric: 117 mm

- Flange width Inch: 4.60 in

- Overall Height Matric: 44.4 mm

- Overall Height Inch: 1.748 in

- Dynamic Load Rating: Cr 25500 N

- Static Load Rating: Cor 15300 N

- Limiting Speed: 5300 r/min

- Clearance: Normal

- Bearing Closures: Two Metal Shields (ZZ)

- Lubrication Type Grease: Shell RL2

- Lubrication Temperature: -20°C to +160°C

- Rolling Element Indicator: Ball

- Bearing Material: Gcr15

- Housing Material: H2000 Cast Iron

- Locking Type: Set Screws

- Product Weight: 1.230 KG

(UCF 209-28) EBC 1-3/4" Flange Block Ball Bearing (4 Hole)

- Manufacturer Name

- EBC

- Weight / Kilogram

- 2.4

- Product Group - BDI

- M06110

- Number of Mounting Holes

- 4

- Mounting Method

- Set Screw

- Housing Style

- 4 Bolt Square Flange Block

- Rolling Element

- Ball Bearing

- Housing Material

- Cast Iron

- Expansion / Non-expansion

- Non-Expansion

- Mounting Bolts

- 1/2 Inch

- Relubricatable

- Yes

- Insert Part Number

- UC209-28

- Seals

- B Seal

- Housing Configuration

- 1 Piece Solid

- Pilot Configuration

- No Pilot

- Inch - Metric

- Inch

- Other Features

- Single Row | Spherical | Gray Epoxy Paint Finish

- Category - BDI

- Flange Block

- UNSPSC

- 31171501

- Harmonized Tariff Code

- 8483.20.40.40

- Noun

- Bearing

- Keyword String

- Flanged

- Manufacturer Item Number

- UCF 209

- Weight / LBS

- 5.28

- Long Description

- 4 Bolt Square Flange Block; 1-3/4" Bore; 5.8" Bolt Circle; 4-1/8" Bolt Spacing; 1 Piece Solid; Set Screw Mount; Cast Iron; Ball Bearing; 1-15/16" Length Thru Bore; Relubricatable; B Seal Seals

- Cartridge Pilot Depth

- 0 Inch | 0 Millimeter

- Bore

- 1.75 Inch | 44.45 Millimeter

- Length Thru Bore

- 1.937 Inch | 49.2 Millimeter

- Cartridge Pilot Diameter

- 0 Inch | 0 Millimeter

- Bolt Spacing

- 4.125 Inch | 104.78 Millimeter

- Nominal Bolt Circle Diameter Round

- 5.8 Inch | 148 Millimeter

(UCF 210-32) Flange Block Ball Bearing (4 Bolt) (50.98MM x 143MM)

(UCFL-204-12) 3/4" Flange Block Ball Bearing (2 Hole)

(UCFL 205-14) 7/8" Flange Block Ball Bearing (2 Hole)

(UCFL 205-15) 15/16" Flange Block Ball Bearing

(UCFL 205-16) 1" Flange Block Ball Bearing (2 Hole)

(UCFL 206-18) 1-1/8" Flange Block Ball Bearing (2 Hole)

(UCFL 207-20) 1-1/4" Flange Block Ball Bearing (2 Hole)

(UCP 204-12) 3/4" Pillow Block Ball Bearing (2 Hole)

Model: UCP204-12

Housing Material: Cast Iron

Bore Size: 3/4" Inch

Static Load Rating: 1,495 Lbs

Dynamic Load Rating: 2,221 Lbs

RPM: 5,800

(UCP 205-14) 7/8" Pillow Block Ball Bearing (2 Hole)

(UCP 206-18) 1-1/8" Pillow Block Ball Bearing (2 Hole)

(UCP 207-20) 1- 1/4" Pillow Block Ball Bearing (2 Hole)

(UCP 207-22) EBC 1-3/8" Pillow Block Ball Bearing (2 Hole)

- Brand

- EBC

- Weight / Kilogram

- 1.698

- Product Group - BDI

- M06110

- Number of Mounting Holes

- 2

- Mounting Method

- Set Screw

- Housing Style

- 2 Bolt Pillow Block

- Rolling Element

- Ball Bearing

- Housing Material

- Cast Iron

- Expansion / Non-expansion

- Non-Expansion

- Mounting Bolts

- 1/2 Inch

- Relubricatable

- Yes

- Insert Part Number

- UC207-22

- Seals

- B Seal

- Housing Configuration

- 1 Piece Solid

- Inch - Metric

- Inch

- Other Features

- Single Row | Spherical | Gray Epoxy Paint Finish

- Category - BDI

- Pillow Block

- UNSPSC

- 31171511

- Harmonized Tariff Code

- 8483.20.40.40

- Noun

- Bearing

- Keyword String

- Pillow Block

- Manufacturer Item Number

- UCP 207

- Weight / LBS

- 3.74

- Long Description

- 2 Bolt Pillow Block; 1-3/8" Bore; 1-7/8" Base to Center Height; Set Screw Mount; Ball Bearing; Relubricatable; Cast Iron; Non-Expansion

- Length Thru Bore

- 1.689 Inch | 42.9 Millimeter

- Bore

- 1.375 Inch | 34.925 Millimeter

- Nominal Bolt Center to Center

- 5 Inch | 127 Millimeter

- Base to Center Height

- 1.875 Inch | 47.625 Millimeter

- Actual Bolt Center to Center

- 5 Inch | 127Millimeter

(UCP 209-28) EBC 1-3/4" Pillow Block (2 Hole)

Model: UCP209-28

Housing Material: Cast Iron

Bore Size: 1-3/4" Inch

Static Load Rating: 4,676 Lbs

Dynamic Load Rating: 5,508 Lbs

RPM: 3,100

(UCP 211-32) 2" Shaft Pillow Block (2 Hole)

Model: UCP211-32

Housing Material: Cast Iron

Bore Size: 2" Inch

Static Load Rating: 6,564 Lbs

Dynamic Load Rating: 7,531 Lbs

RPM: 2,500

Roller Chain #50 (Sold By the Foot)

- Pitch (P): 0.625 inch (15.875 mm)

- Roller Diameter (d1 max): 0.4 inch (10.16 mm)

- Width Between Inner Plates (b1 min): 0.370 inch (9.4 mm)

- Pin Diameter (d2 max): 0.2 inch (5.08 mm)

- Pin Lenght (L max): 0.815 inch (20.70 mm)

- Pin Lenght (Lc max): 0.874 inch (22.20 mm)

- Inner Plate Depth (h2 max): 0.594 inch (15.09 mm)

- Plate Thickness (T max): 0.080 inch (2.03 mm)

- Ultimate Tensile Strenght (Q min): 22.20/5045 kN/LB

- Average Tensile Strenght (Qo): 29.4 kN

- Weight (q): 0.685 lb/ft (1.02 kg/m)

Roller Chain #60 (Sold By the Foot)

- Pitch (P): 0.75 inch (19.050 mm)

- Roller Diameter (d1 max): 0.469 inch (11.91 mm)

- Width Between Inner Plates (b1 min): 0.495 inch (12.57 mm)

- Pin Diameter (d2 max): 0.234 inch (5.94 mm)

- Pin Lenght (L max): 1.02 inch (25.90 mm)

- Pin Lenght (Lc max): 1.09 inch (27.70 mm)

- Inner Plate Depth (h2 max): 0.708 inch (18.00 mm)

- Plate Thickness (T max): 0.095 inch (2.42 mm)

- Ultimate Tensile Strenght (Q min): 31.80/7227 kN/LB

- Average Tensile Strenght (Qo): 41.5 kN

- Weight (q): 1.008 lb/ft (1.5 kg/m)

Roller Chain #80 x 10 Foot

- Pitch (P): 1.0 inch (25.400 mm)

- Roller Diameter (d1 max): 0.625 inch (15.88 mm)

- Width Between Inner Plates (b1 min): 0.620 inch (15.75 mm)

- Pin Diameter (d2 max): 0.311 inch (7.92 mm)

- Pin Length (L max): 1.287 inch (32.70 mm)

- Pin Length (Lc max): 1.377 inch (35.00 mm)

- Inner Plate Depth (h2 max): 0.944 inch (24.00 mm)

- Plate Thickness (T max): 0.128 inch (3.25 mm)

- Ultimate Tensile Strenght (Q min): 56.70/12886 kN/LB

- Average Tensile Strenght (Qo): 69.4 kN

- Weight (q): 1.747 lb/ft (2.6 kg/m)

Connecting Link #50 Chain

- Roller Chain Link Item: Connecting Link

- Roller Chain Link Type: Standard Riveted

- Industry Chain Size: 50

- Chain Link Material: Carbon Steel

- Industry Chain Pitch: 5/8 in

- Number of Strands: Single

- ANSI Chain Size: 50

- Inside Pin Dia.: 0.2 in

Off-Set Link #60 Chain

- Roller Chain Link Item: Offset Link

- Roller Chain Link Type: Standard Riveted

- Industry Chain Size: 60

- Chain Link Material: Carbon Steel

- Industry Chain Pitch: 3/4 in

- Number of Strands: Single

- Chain Link Overall Width: 1.23 in

- Chain Roller Dia.: 0.469 in

Connecting Link (#35 Chain)

- Roller Chain Link Item: Connecting Link

- Roller Chain Link Type: Standard Riveted

- Industry Chain Size: 35

- Chain Link Material: Carbon Steel

- Industry Chain Pitch: 3/8 in

- Number of Strands: Single

- Inside Pin Dia.: 0.141 in

- ANSI Chain Size: 35

- Pitch: 0.375"

- Item: Connecting Link

- Temp. Range: 15 Degrees to 300 Degrees F

- Type: Single Strand

- Material: Carbon Steel

- Roller Chain Standard: ANSI

- Pin Outside Diameter: 0.141 in

- Link Type: Connecting Link

- Roller Diameter: 3/16 in

- Plate Height: 0.307 in, 0.354 in

- Features: Heat Treatment, Prelubrication

- Chain Number: 35

- Chain Overall Width: 1/2 in

- Inside Width: 3/16 in

- Maximum Operating Temperature: 300 Degrees F

- Number of Strands (broad rename): Single

- Pin Contruction: Riveted Pin

- Minimum Operating Temperature: 15 Degrees F

- For Chain Style (combined): 35 Steel Regular

- For Chain Number: 35

- Chain Construction: Riveted Pin

- Standards: ANSI, ASME

- For Chain Style: Standard Roller Chains

- Plate Thickness: 0.05 in

- Heavy Series: No

- Series: RS

- Heavy Series (from Heavy): Regular

- Working Load Limit: 480 lb

- Application: Automobile Engines, Container Straddle Carriers, Crawler Drills, Draw Benches, Marine Diesel Engines, Oil-Well Drilling Equipment, Pump Drives, Roller Tables, Tilting Tables

- Link Style: Connecting Link

- Country of Origin (subject to change): Taiwan, Province of China

Off-Set Link # 50 Chain

- Chain Size & Pitch: 50 / 5/8 in

- Link Type: Offset

- Link Material: Carbon Steel

- Number of Strands Across: 1 Chain

- Construction: Riveted Roller

- Diameter: 0.400 in

- Inside Width: 0.375 in

- Link Plate Height: 0.591 in

- Link Plate Thickness: 0.08 in

- Pin Diameter: 0.2 in

- Chain Overall Width: 0.88 in

- Series: Standard

Reel Chain #35 (sold by the foot)

- Pitch (P): 0.375 inch (9.525 mm)

- Roller Diameter (d1 max): 0.2 inch (5.08 mm)

- Width Between Inner Plates (b1 min): 0.188 inch (4.77 mm)

- Pin Diameter (d2 max): 0.141 inch (3.58 mm)

- Pin Lenght (L max): 0.488 inch (12.40 mm)

- Pin Lenght (Lc max): 0.518 inch (13.17 mm)

- Inner Plate Depth (h2 max): 0.354 inch (9.0 mm)

- Plate Thickness (T max): 0.051 inch (1.30 mm)

- Ultimate Tensile Strenght (Q min): 7.90/1795 kN/LB

- Average Tensile Strenght (Qo): 10.8 kN

Connecting Link #60 Chain

- Roller Chain Link Item: Connecting Link

- Roller Chain Link Type: Standard Riveted

- Industry Chain Size: 60

- Chain Link Material: Carbon Steel

- Industry Chain Pitch: 3/4 in

- Number of Strands: Single

- Chain Link Overall Width: 1.23 in

- Chain Roller Dia.: 0.469 in

B-24 V-Belt

27" Long

5/8" Wide

Abkt Roper Stockman Chaparral – Series 2.5″ Blade Red Bone

- UPC: 815949011044

- Weight: 0.18 pounds

- Dimensions: 4.5 × 1.5 × 0.75 inches

- Model/Part/Item Number - RP0001CRB

- Brand: Roper Knives

- Roper 0001CRB - Stockman Chaparral Series

- 3.5" closed

- Satin finish 1065 carbon steel clip, sheepsfoot, and spey blades

- Red jigged bone handle

- Nickel silver bolster(s)

- Inlay shield

- Chaparral Series

- Boxed

- Made in China.

CASE Executive Lockback 3 In. Folding Knife Stainless Steel

Executive Lockback folding knife featuring a brushed stainless steel handle. Includes a durable Tru-Sharp surgical steel blade. 3-1/8 In. closed. Weighs 1.0 Oz. Boxed packaging.

Model: # 00004

Schrade Old Timer Brown Sawcut Hawkbill Linerlock

Weight:0.28 LBS

Blade Material:7Cr17Mov Stainless Steel

Blade Style:Hawkbill

Blade Thickness:.06'

Web Brand:Old Timer

Country of Origin:China

Edge Type:Plain

Exclusive:No

Handedness:Ambidextrous

Handle Material:Polymer

Knife Style:EDC

Knife Type:Folding Knives

Lock Type:Linerlock

Flammable:No

Paypal Restricted:No

Blade Length:3"

Model Number:1187218/216OT

Overall Length:7.00'

CA Prop 65 Warning:?WARNING: Cancer and Reproductive Harm - www.P65Warnings.ca.gov

Closed Lenght:4'

Schrade® 278 - Jackmaster Barlow 2.4" Clip Point/Drop Point Folding Multiknife

Blade Material: 3Cr13MoV stainless steel

Handle: Brown celluloid

Length: 2.4 (blade) 5.7 (overall)

- Not legal for sale in the following states: New Jersey, New York, Rhode Island, Wisconsin, Texas, Illinois, Michigan, Massachusetts and Hawaii

11343 Male NPT Swivel 43 Series Parker Crimp Fitting

- Material: Steel

- Trade Name: Parkrimp

- Series: 43

- Configuration Type: Male NPTF Pipe - Swivel - Straight

- Inch/Metric: Inch

- Parker Division: Hose Products

- Parker Group: Fluid Connector

- Inner Diameter Inch/mm: Inch

- End 1 Type: Inch

- Hose Connection Type: Permanent

- Fitting End: Male

- Fitting Type: NPT Pipe

- Fitting Movement: Rigid

- Fitting Shape: Straight

- Fitting Connection: Crimp

10243 Female NPT Rigid Parker Series 43 Crimp Fitting

- Material: Steel

- Trade Name: Parkrimp

- Series: 43

- Configuration Type: Female NPTF Pipe - Rigid - Straight

- Inch/Metric: Inch

- Parker Division: Hose Products

- Parker Group: Fluid Connector

- Inner Diameter Inch/mm: Inch

- End 1 Type: Inch

- Hose Connection Type: Permanent

- Fitting End: Female

- Fitting Type: NPTF Pipe

- Fitting Movement: Rigid

- Fitting Shape: Straight

- Fitting Connection: Crimp

11L43 NPT Male Swivel Elbow Parker 43 Series Crimp Fitting

- Material: Steel

- Trade Name: Parkrimp

- Series: 43

- Configuration Type: Male NPTF Pipe - Swivel - 90 Degree

- Inch/Metric: Inch

- Parker Division: Hose Products

- Parker Group: Fluid Connector

- Inner Diameter Inch/mm: Inch

- End 1 Type: Inch

- Hose Connection Type: Permanent

- Fitting End: Male

- Fitting Type: NPTF Pipe

- Fitting Movement: Swivel

- Fitting Shape: Straight

- Fitting Connection: Crimp

1S243 Female NPT Swivel Parker 43 Series Crimp Fitting

- Material: Steel

- Trade Name: Parkrimp

- Series: 43

- Configuration Type: Female NPTF Pipe - Swivel - Straight

- Inch/Metric: Inch

- Parker Division: Hose Products

- Parker Group: Fluid Connector

- Inner Diameter Inch/mm: Inch

- End 1 Type: Inch

- Hose Connection Type: Permanent

- Fitting End: Female

- Fitting Type: NPTF Pipe

- Fitting Movement: Swivel

- Fitting Shape: Straight

- Fitting Connection: Crimp

10743 Female NPT Swivel Parker 43 Series Crimp Fitting

Material: Steel

Trade Name: Parkrimp

Series: 43

Configuration Type: Female NPSM Pipe - Swivel - (60° Cone)

Inch/Metric: Inch

Parker Division: Hose Products

Parker Group: Fluid Connector

Inner Diameter Inch/mm: Inch

End 1 Type: Inch

Hose Connection Type: Permanent

Fitting End: Female

Fitting Type: NPTF Pipe

Fitting Movement: Swivel

Fitting Shape: Straight

Fitting Connection: Crimp

10543 Male O-ring Boss Rigid Parker 43 Series Crimp Fitting

Material: Steel

Trade Name: Parkrimp

Series: 43

Configuration Type: Male SAE Straight Thread with O-Ring - Rigid

Inch/Metric: Inch

Parker Division: Hose Products

Parker Group: Fluid Connector

Inner Diameter Inch/mm: Inch

End 1 Type: Inch

Hose Connection Type: Permanent

Fitting End: Male

Fitting Type: Male SAE Straight Thread with O-Ring

Fitting Movement: Rigid

Fitting Shape: Straight

Fitting Connection: Crimp

10G43 Male O-ring Boss Swivel Parker 43 Series Crimp Fitting

Material: Steel

Trade Name: Parkrimp

Series: 43

Configuration Type: Male SAE Straight Thread with O-Ring - Straight - Swivel

Inch/Metric: Inch

Parker Division: Hose Products

Parker Group: Fluid Connector

Inner Diameter Inch/mm: Inch

End 1 Type: Inch

Hose Connection Type: Permanent

Fitting End: Male

Fitting Type: Male SAE Straight Thread with O-Ring

Fitting Movement: Swivel

Fitting Shape: Straight

Fitting Connection: Crimp

10L43 Male O-ring Boss Swivel Elbow Parker 43 Series Crimp Fitting

Material: Steel

Trade Name: Parkrimp

Series: 43

Configuration Type: Male SAE Straight Thread with O-Ring - Elbow - Swivel

Inch/Metric: Inch

Parker Division: Hose Products

Parker Group: Fluid Connector

Inner Diameter Inch/mm: Inch

End 1 Type: Inch

Hose Connection Type: Permanent

Fitting End: Male

Fitting Type: Male SAE Straight Thread with O-Ring

Fitting Movement: Swivel

Fitting Shape: 90 Degree

Fitting Connection: Crimp

10343 Male JIC 37° Straight 43 Series Parker Crimp Fitting

Material: Steel

Trade Name: Parkrimp

Series: 43

Configuration Type: Male JIC 37°- Straight- Rigid

Inch/Metric: Inch

Parker Division: Hose Products

Parker Group: Fluid Connector

Inner Diameter Inch/mm: Inch

End 1 Type: Inch

Hose Connection Type: Permanent

Fitting End: Male

Fitting Type: Male JIC Straight Thread with O-Ring

Fitting Movement: Rigid

Fitting Shape: Straight

Fitting Connection: Crimp

10643 Female JIC 37° Straight 43 Series Parker Crimp Fitting

Material: Steel

Trade Name: Parkrimp

Series: 43

Configuration Type: Female JIC 37°- Straight- Rigid

Inch/Metric: Inch

Parker Division: Hose Products

Parker Group: Fluid Connector

Inner Diameter Inch/mm: Inch

End 1 Type: Inch

Hose Connection Type: Permanent

Fitting End: Female

Fitting Type: Female JIC 37°

Fitting Movement: Swivel

Fitting Shape: Straight

Fitting Connection: Crimp

13743 Female JIC 37°, 45° Elbow 43 Series Parker Crimp Fitting

Material: Steel

Trade Name: Parkrimp

Series: 43

Configuration Type: Female JIC 37°-45° Elbow - Swivel

Inch/Metric: Inch

Parker Division: Hose Products

Parker Group: Fluid Connector

Inner Diameter Inch/mm: Inch

End 1 Type: Inch

Hose Connection Type: Permanent

Fitting End: Female

Fitting End: Female JIC Straight Thread

Fitting Movement: Rigid

Fitting Shape: Straight

Fitting Connection: Crimp

Dewalt XR 20V 1/2" Drive Impact Kit (DCF961)

Introducing the Dewalt XR 20V 1/2" Drive Impact (DCF961) - a powerful and reliable tool built for heavy-duty tasks. Get the job done efficiently and effortlessly with this professional-grade impact driver.

Includes Impact, Battery, Charger, and Carrying Bag.

- GET UP TO 71% MORE TORQUE*** for tough fastening applications.

- COMPLETE A WIDE VARIETY OF FASTENING APPLICATIONS with 1200 ft-lbs of max fastening torque and 1750 ft-lbs of max breakaway torque.

- ILLUMINATE DARK WORKSPACES when using the on-tool LED work light.

- EXPERIENCE POWER™ Industry's Highest Rated Max Torque Cordless1/2 in. Impact Wrench**

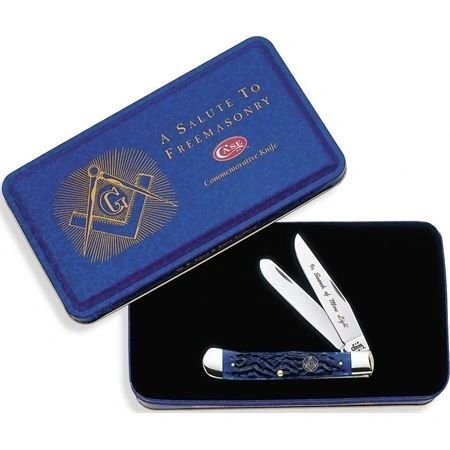

Case XX Masonic Blue Bone Standard Jig Trapper w/ Tin

Masonic blue bone standard jig Trapper folding knife. Features Tru-Sharp surgical steel embellished clip blade and spey blade. The clip blade is commonly used as a multi-purpose blade and preferred for detail work while the spey blade is commonly used as an all-purpose utility blade. This knife is constructed with Case Tru-Sharp stainless steel which is a special high-carbon steel that helps the blades hold an edge longer than conventional steel. It also offers extraordinary blade strength and corrosion resistance. Comes conveniently packaged in a gift tin with certification of authenticity. Limited lifetime warranty. Blade Length: 3.25 In., 3.27 In. Overall Length: Closed Length: 4.125 In. Weight: 4 Oz. Blade Material: Stainless Steel Handle Material: Blue Bone Color: Blue Lockable: No Sheath Included: Warning: Cancer and Reproductive Harm - www.P65Warnings.ca.gov -

13943 Female JIC 37°, 90° Elbow 43 Series Parker Crimp Fitting

Material: Steel

Trade Name: Parkrimp

Series: 43

Configuration Type: Female JIC 37°-90° Elbow - Swivel

Inch/Metric: Inch

Parker Division: Hose Products

Parker Group: Fluid Connector

Inner Diameter Inch/mm: Inch

End 1 Type: Inch

Hose Connection Type: Permanent

Fitting End: Female

Fitting End: Female JIC Straight Thread

Fitting Movement: Swivel

Fitting Shape: 90 Degree

Fitting Connection: Crimp

1L943 Female JIC 37°, 90° Elbow Medium Drop 43 Series Parker Crimp Fitting

Material: Steel

Trade Name: Parkrimp

Series: 43

Configuration Type: Female JIC 37°-90° Elbow - Swivel

Inch/Metric: Inch

Parker Division: Hose Products

Parker Group: Fluid Connector

Inner Diameter Inch/mm: Inch

End 1 Type: Inch

Hose Connection Type: Permanent

Fitting End: Female

Fitting End: Female JIC Straight Thread

Fitting Movement: Swivel

Fitting Shape: 90 Degree

Fitting Connection: Crimp

14143 Female JIC 37°, 90° Elbow Long Drop 43 Series Parker Crimp Fitting

Material: Steel

Trade Name: Parkrimp

Series: 43

Configuration Type: Female JIC 37°-90° Elbow - Swivel

Inch/Metric: Inch

Parker Division: Hose Products

Parker Group: Fluid Connector

Inner Diameter Inch/mm: Inch

End 1 Type: Inch

Hose Connection Type: Permanent

Fitting End: Female

Fitting End: Female JIC Straight Thread

Fitting Movement: Swivel

Fitting Shape: 90 Degree

Fitting Connection: Crimp

10443 Male SAE 45°, Straight, 43 Series Parker Crimp Fitting

Material: Steel

Trade Name: Parkrimp

Series: 43

Configuration Type: Male SAE 45°- Straight - Rigid

Inch/Metric: Inch

Parker Division: Hose Products

Parker Group: Fluid Connector

Inner Diameter Inch/mm: Inch

End 1 Type: Inch

Hose Connection Type: Permanent

Fitting End: Male

Fitting End: Male SAE Straight Thread

Fitting Movement: Rigid

Fitting Shape: Straight

Fitting Connection: Crimp

10843 Female SAE 45°, Straight, Swivel 43 Series Parker Crimp Fitting

Material: Steel

Trade Name: Parkrimp

Series: 43

Configuration Type: Female SAE 45°- Straight - Swivel

Inch/Metric: Inch

Parker Division: Hose Products

Parker Group: Fluid Connector

Inner Diameter Inch/mm: Inch

End 1 Type: Inch

Hose Connection Type: Permanent

Fitting End: Female

Fitting End: Female SAE Straight Thread

Fitting Movement: Swivel

Fitting Shape: Straight

Fitting Connection: Crimp

17943 Female SAE 45°, 90° Elbow 43 Series Parker Crimp Fitting

Material: Steel

Trade Name: Parkrimp

Series: 43

Configuration Type: Female SAE 45°-90° Elbow - Swivel

Inch/Metric: Inch

Parker Division: Hose Products

Parker Group: Fluid Connector

Inner Diameter Inch/mm: Inch

End 1 Type: Inch

Hose Connection Type: Permanent

Fitting End: Female

Fitting End: Female SAE Straight Thread

Fitting Movement: Swivel

Fitting Shape: 90 Degree

Fitting Connection: Crimp

11243 Female Ferulok Flareless (24° Cone) Parker 43 Series Crimp Fitting

Material: Steel

Trade Name: Parkrimp

Series: 43

Configuration Type: Female Ferulok Flareless -Straight-Swivel - (24° Cone)

Inch/Metric: Inch

Parker Division: Hose Products

Parker Group: Fluid Connector

Inner Diameter Inch/mm: Inch

End 1 Type: Inch

Hose Connection Type: Permanent

Fitting End: Female

Fitting End: Female Ferulok Flareless Straight Thread

Fitting Movement: Swivel

Fitting Shape: 90 Degree

Fitting Connection: Crimp

11143 Male Ferulok Flareless - Rigid - (24° Cone with Nut and Ferrule) Parker 43 Series Crimp Fitting

Material: Steel

Trade Name: Parkrimp

Series: 43

Configuration Type: Male Ferulok Flareless - Rigid - (24° Cone with Nut and Ferrule)

Inch/Metric: Inch

Parker Division: Hose Products

Parker Group: Fluid Connector

Inner Diameter Inch/mm: Inch

End 1 Type: Inch

Hose Connection Type: Permanent

Fitting End:Male

Fitting End: Male Ferulok Flareless

Fitting Movement: Swivel

Fitting Shape: Straight

Fitting Connection: Crimp

12843 Male Inverted SAE 45°- Straight - Swivel Parker 43 Series

Material: Steel

Trade Name: Parkrimp

Series: 43

Configuration Type: Male Inverted SAE 45°- Straight - Swivel

Inch/Metric: Inch

Parker Division: Hose Products

Parker Group: Fluid Connector

Inner Diameter Inch/mm: Inch

End 1 Type: Inch

Hose Connection Type: Permanent

Fitting End:Male

Fitting End: Male Inverted SAE 45°

Fitting Movement: Swivel

Fitting Shape: Straight

Fitting Connection: Crimp

164C-10 Parker Brass

Compression Forged Tee Fitting

Connection Type:Compression

Product Style:Tube to Tube

Connection 2 Type:Compression

Connection 1 Size:5/8 inch

Connection 3 Size:5/8 inch

Connection 2 Size:5/8 inch

Connection 1 Type:Compression

Maximum Operating Pressure:68.9 bar, 1,000 psi, 14 bar, 200 psi

Shape:Tee

Tube Material:Copper, Aluminum, Thermoplastic

Nut Material:Brass

Sleeve Material:Brass, Acetal

164C-12 Parker Brass

Compression Forged Tee Fitting

Connection Type:Compression

Product Style:Tube to Tube

Connection 2 Type:Compression

Connection 1 Size:3/4 inch

Connection 3 Size:3/4 inch

Connection 2 Size:3/4 inch

Connection 1 Type:Compression

Maximum Operating Pressure:68.9 bar, 1,000 psi, 14 bar, 200 psi

Shape:Tee

Tube Material:Copper, Aluminum, Thermoplastic

Nut Material:Brass

Sleeve Material:Brass, Acetal

164C-2 Parker Brass Compression Forged Tee Fitting

Connection Type:Compression

Product Style:Tube to Tube

Connection 2 Type:Compression

Connection 1 Size: 1/8 inch

Connection 3 Size:1/8 inch

Connection 2 Size:1/8 inch

Connection 1 Type:Compression

Maximum Operating Pressure:68.9 bar, 1,000 psi, 14 bar, 200 psi

Shape:Tee

Tube Material:Copper, Aluminum, Thermoplastic

Nut Material:Brass

Sleeve Material:Brass, Acetal

164C-4 Parker Brass Compression Forged Tee Fitting

Connection Type:Compression

Product Style:Tube to Tube

Connection 2 Type:Compression

Connection 1 Size:1/4 inch

Connection 3 Size:1/4 inch

Connection 2 Size:1/4 inch

Connection 1 Type:Compression

Maximum Operating Pressure:68.9 bar, 1,000 psi, 14 bar, 200 psi

Shape:Tee

Tube Material:Copper, Aluminum, Thermoplastic

Nut Material:Brass

Sleeve Material:Brass, Acetal

164C-5 Parker Brass Compression Forged Tee Fitting

Connection Type:Compression

Product Style:Tube to Tube

Connection 2 Type:Compression

Connection 1 Size:5/16 inch

Connection 3 Size:5/16 inch

Connection 2 Size:5/16 inch

Connection 1 Type:Compression

Maximum Operating Pressure:68.9 bar, 1,000 psi, 14 bar, 200 psi

Shape:Tee

Tube Material:Copper, Aluminum, Thermoplastic

Nut Material:Brass

Sleeve Material:Brass, Acetal

164C-6 Parker Brass Compression Forged Tee Fitting

Connection Type:Compression

Product Style:Tube to Tube

Connection 2 Type:Compression

Connection 1 Size:3/8 inch

Connection 3 Size:3/8 inch

Connection 2 Size:3/8 inch

Connection 1 Type:Compression

Maximum Operating Pressure:68.9 bar, 1,000 psi, 14 bar, 200 psi

Shape:Tee

Tube Material:Copper, Aluminum, Thermoplastic

Nut Material:Brass

Sleeve Material:Brass, Acetal

164C-8 Parker Brass Compression Forged Tee Fitting

Connection Type:Compression

Product Style:Tube to Tube

Connection 2 Type:Compression

Connection 1 Size:1/2 inch

Connection 3 Size:1/2 inch

Connection 2 Size:1/2 inch

Connection 1 Type:Compression

Maximum Operating Pressure:68.9 bar, 1,000 psi, 14 bar, 200 psi

Shape:Tee

Tube Material:Copper, Aluminum, Thermoplastic

Nut Material:Brass

Sleeve Material:Brass, Acetal

165C Parker Forged Brass 90° Elbow

Connection Type:Compression

Product Style:Tube to Tube

Connection 2 Type:Compression

Connection 1 Type:Compression

Maximum Operating Pressure:68.9 bar, 1,000 psi, 14 bar, 200 psi

Shape:90° Elbow

Tube Material:Copper, Aluminum, Thermoplastic

Nut Material:Brass

Sleeve Material:Brass, Acetal

11543 SAE Code 61 Flange Head 43 Series Parker Crimp Fitting

Material: Steel

Shape: Straight

Style: SAE Code 61 Flange Head

11943 SAE Code 61 Flange Head 43 Series Parker Crimp Fitting

Shape: 90° Elbow

Material: Steel

Style: SAE Code 61 Flange Head

16743 Inverted Flare 45° Elbow Parker 43 Series Crimp Fitting

Product Style:Male Inverted SAE 45° - Swivel

Shape: Elbow 45°

Materials of Construction: Steel

Shape: 45° Elbow

Product Style: Male Inverted SAE 45° - Swivel

16943 Inverted Flare 90° Elbow Parker 43 Series Crimp Fitting

Product Style: Male Inverted SAE 90° - Swivel

Shape: Elbow 90°

Materials of Construction: Steel

11743 Code 61 Flange 45° Elbow Parker Crimp Fitting

Shape: 45°

Style: SAE Code 61 Flange Head

Product Style: SAE Code 61 Flange Head

Materials of Construction: Steel

16A43 Code 62 Flange Parker 43 Series Crimp Fitting

Shape: Straight

Product Style: SAE Code 62 Flange Head

Materials of Construction: Steel

16F43 Code 62 Flange 45° Elbow Parker 43 Series Crimp Fitting

Shape: 45° Elbow

Style: SAE Code 61 Flange Head

Product Style: SAE Code 61 Flange Head

Materials of Construction: Steel

16N43 Code 2 Flange 90° Elbow Parker 43 Series Crimp Fitting

Shape: 90°

Style: SAE Code 61 Flange Head

Product Style: SAE Code 61 Flange Head

Materials of Construction: Steel

1JS43 Seal-Lok Parker 43 Series Crimp Fitting

Product Style: Female Seal-Lok® - Swivel

Shape: Straight - Long

Materials of Construction: Steel

1J743 Seal-Lok 45° Elbow Parker 43 Series Crimp Fitting

Shape: 45°

Product Style: Female Seal-Lok® - Swivel

Shape: Straight - Long

Materials of Construction: Steel

1J943 Seal-Lok 90° Elbow Parker 43 Series Crimp Fitting

Shape: 90°

Product Style: Female Seal-Lok®

Materials of Construction: Steel

1J043 Seal-Lok Male 43 Series Crimp Fitting

Product Style: Male Seal-Lok® - Rigid

Shape: Straight

Materials of Construction: Steel

1J143 Seal-Lok Long Drop 90° Elbow Parker 43 Series Crimp Fitting

Product Style: Female Seal-Lok® - Swivel

Shape: Elbow 90° - Long Drop

Materials of Construction: Steel

1J543 Seal-Lok 90° Medium Drop Parker 43 Series Crimp Fitting

Product Style: Female Seal-Lok® - Swivel

Shape: Elbow 90° - Medium Drop

Materials of Construction: Steel

11D43-6-4 Metric L Standpipe Parker 43 Series Crimp Fitting - Hydraulic Hose Fittings

Crimp Style Hydraulic Hose Fitting - 43 Series Fittings | #11D43-6-4

Parker’s best-selling 43 Series crimp style hydraulic fittings are a complete range of cost-effective, permanent, crimp-style hydraulic hose fittings for use with the Parkrimp family of crimpers.

TECHNICAL DETAILS:

Materials of Construction: Steel

Port Connection:6 mm

Hex Type: n/a

Shape: Straight

Hose I.D. (size):-4

Product Style: Male Standpipe Metric L - Rigid

Disclaimer: The user, through its own analysis and testing, is solely responsible for making the final selection of the system and components and assuring that all performance, endurance, maintenance, safety and warning requirements of the application are met. The user must analyze all aspects of the application, follow applicable industry standards, and follow the information concerning the product in the current product catalog and in any other materials provided from Parker or its subsidiaries or authorized distributors. Refer to Fluid Connectors safety guide.

Hose Inside Diameter:-4 (Size), 1/4 inch

Port Size: 6 mm

Connection Size :n/a

Flange Size: n/a

Product Style: Male Standpipe Metric L - Rigid

Shape: Straight

Materials of Construction: Steel

Banjo Port Diameter: n/a

Nut Hex Size: n/a

Back-Up Hex Size: n/a

Safety Notice:

For more information go to: https://ph.parker.com/

ITEM INFORMATION:

The 43 Series of hydraulic hose fittings from Parker Hannifin is renowned for its ease of assembly, wide selection of shape and end formations, hose compatibility, and extensive use across markets. This cost-effective line of permanent crimp-style hydraulic fittings is designed for use with Parkcrimp crimpers to deliver “bite-the-wire” sealing and holding power. When used with Parker’s No-Skive hoses, 43 Series fittings can be assembled without removing the outer hose cover, eliminating premature hose failure caused by skiving too long or too short.

43 Series fittings feature one-piece construction with chromium-6-free plating, and are compatible with petroleum-based hydraulic fluids and lubricating oils and with phosphate-ester-based hydraulic fluids. Applications include hydraulic industry standard, constant working pressure, high temperature, low temperature, suction and return. Available in sizes from ¼-inch to 2 inches in a wide variety of end formations, the 43 Series is offered in more than 2,500 configurations and is available around the world. For highly corrosive applications, 43 Series fittings also are available in stainless steel.

Markets:

• Transportation

• RV & Bus

• Military

• Construction

• Agriculture

• Grounds & Building Maintenance

• Forestry

• Railroad

• Utility Equipment

• Personnel Lift Equipment

• Machine Tool

• Oil Field Service

• Waste & Refuse

• Material Handling

• Marine

• Paving & Road Maintenance

• Ground Support Equipment

• Industrial

• Mining

Features/Benefits:

• Easy push on force

• Imperial HEX

• Stainless steel option available

• Wide range of end configurations

• One piece reduces complexity and leakage path

• No-Skive technology offers easy, efficient, and safe production processes

Applications:

• Petroleum base hydraulic fluids and lubricating oils

• Phosphate-ester base hydraulic fluids

Compatible Hoses:

• 301LT

• 302

• 304

• 351TC, 351ST

• 387/TC/ST (-4 through -20 only)

• 422

• 424

• 426

• 431

• 436

• 451TC, 451ST

• 471TC, 471ST

• 472TC

• 482TC, 482ST

• 487/TC/ST (-4 through -16 only)

• 722/TC/ST

• 787/TC/ST (-4 and -6 only)

• 797/TC/ST (-4 and -6 only)

• 881

• GST II Series 7092

Diablo Hammer Bit 6" Carbide Tipped 1/8", 5/32, 3/16, 1/4, 5/16, 3/8, 1/2

The Diablo Hammer Bit 6" Carbide Tipped offers a variety of sizes for precise drilling in different materials. Perfect for professional use in the hose supply industry.

- Diablo made carbide tip withstands impact and high-heat applications for superior life versus standard multi-purpose hammer drill bits

- Multi-ground grip point tip delivers stability and accuracy required for fast, precise holes

- Optimized flute design removes dust/chip build-up faster, keeping the carbide tip cooler for ultimate strength and durability

- Impact Strong™ increases shank stability and durability

- More holes per charge in cordless impact and drill drivers

- Maximum performance in hammer or rotary drilling applications

DeWalt 20V MAX* XR Brushless 3/4 in. High Torque Impact Wrench w/ Hog Ring Anvil POWERSTACK 5.0Ah Kit - No. DCF964GH1

Complete tough jobs utilizing the power of the 20V MAX* XR 3/4" High Torque Impact Wrench. The industry's highest rated max torque cordless 3/4" impact wrench** delivers up to 102% more torque***, making it ideal for heavy-duty applications. This tool features a glass-filled nylon housing to help protect against oils and solvents. Other features such as PRECISION WRENCH mode, which helps prevent overtightening and fastener run-off, as well as a 4-mode push button switch, to easily change speeds and LED brightness, are included to help maximize efficiency and productivity on the jobsite. Battery, charger and carry bag included

- THE INDUSTRY'S HIGHEST RATED MAX TORQUE CORDLESS 3/4" IMPACT WRENCH** - delivers 1420 ft-lbs of max fasting torque and 1900 ft-lbs of max breakaway torque

- THE INDUSTRY'S HIGHEST RATED MAX TORQUE CORDLESS 3/4" IMPACT WRENCH** - delivers 1420 ft-lbs of max fastening torque and 1900 ft-lbs of max breakaway torque

- GET UP TO 102% MORE TORQUE - to complete tough fastening applications

- 3 SPEED SETTINGS AND PRECISION WRENCH MODE - to help prevent overtightening and fastener run-off

- COMBATS HARSH ENVIRONMENTS - resist damage from oil, grease, and solvents with oil-resistant tool and battery housing

- (1) DCF964 20V MAX* XR Brushless 3/4 in. High Torque Impact Wrench w/ Hog Ring Anvil

- (1) DCBP520 20V MAX XR POWERSTACK 5.0Ah Battery

- (1) Charger

- (1) Kit Bag

Milwaukee M18 FUEL 2880-20 Grinder, Tool Only, 18 V, 5/8-11 Spindle, 4-1/2, 5 in Dia Wheel, 8500 rpm Speed

Speed Rating:8500 rpm

Spindle Size:5/8-11

Only Voltage Rating:18 V

Wheel Diameter:4-1/2 5 in

Features

- 100% tool-free make all accessory changes and guard adjustments without a wrench for increased productivity

- Paddle switch design provides increased comfort and ease-of-use when operating in various positions

- POWERSTATE™ brushless motor delivers maximum power and up to 10X longer motor life

- REDLINK PLUS™ intelligence provides optimized performance, electronic clutch and overload protection using total system communication between tool, battery and charger

- REDLITHIUM™ XC5.0 battery pack provides great pack construction, electronics and performance to deliver 2X more runtime and more work over pack life

- Power to grind world's first cordless grinder with corded performance

- Durability same metal housing and gearing system as legendary high-performance corded grinders

DEWALT DW235G Electric Drill, 7.8 A, 1/2 in Chuck, Keyed Chuck

The DW235G 1/2 in VSR drill is constructed with helical-cut steel and heat-treated steel gears for long life and durability. Rubber grip and two-finger trigger provides comfort and control.

Amp Rating:7.8

A Chuck Size:1/2 in Chuck

Handle Type: Rubber Grip w

Handle Type:Rubber Grip

Includes:(1) 360 deg Side Handle (1) Chuck Key with Holder

Features

- Helical-cut steel, heat-treated steel gears for long life and durability

- Two-finger trigger for increased comfort

- Metal gear housing for jobsite durability and increased reliability

- 360 deg side handle for greater control and versatility

DeWalt BATTERY 20V 5AH DCBP520

DCBP520 POWER STACK 20V 5AH

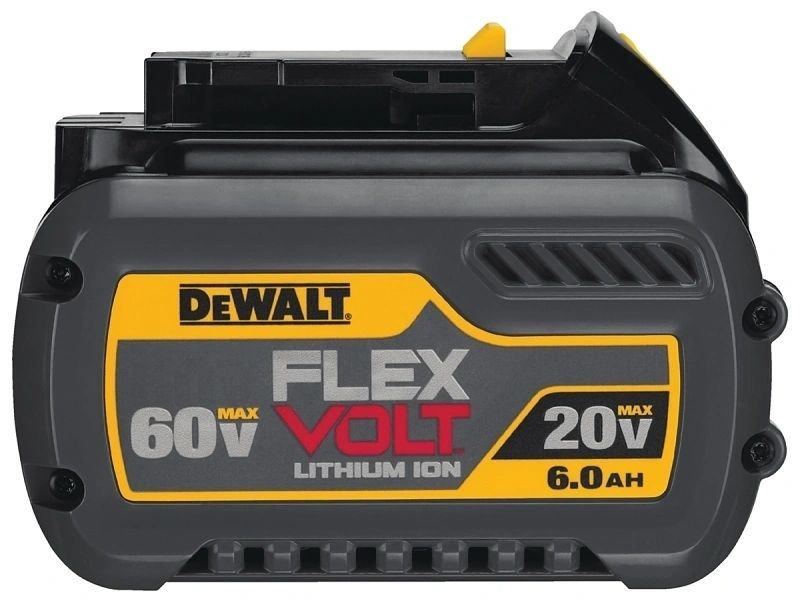

DEWALT DCB606 Rechargeable Battery Pack, 20/60 V Battery, 6 Ah, 1 hr Charging

The DCB606 20 V/60 V Max battery pack changes voltage when you change tools, powering a line of powerful 60 V Max tools, 120 V Max tools and backwards compatible to existing 20 V Max tools and chargers. The battery pack is smart enough to know when to provide runtime for 20 V Max tools (6 Ah) and power in the new 60 V Max and 120 V Max tools.

Battery Capacity:6 Ah Battery

Voltage:20/60 V

Charging Time:1 Hour

Features

- The power of corded with the flexibility of cordless

- 3X power compared to DC9096 18 V battery

- LED state of charge display

- 4X runtime compared to DCB201 1.5 Ah battery pack

- Durable construction with a single piece cell holder

- Tri-platform compatibility 20 V Max, 60 V Max and 120 V Max

Baron 63715 Cord, 5/32 in Dia, 100 ft L, 110 lb Working Load, Polyester, Camo

Baron Cord, Working Load Limit: 110 lb, Construction: Paracord, Polyester, Camo, 5/32 in Dia, 100 ft L

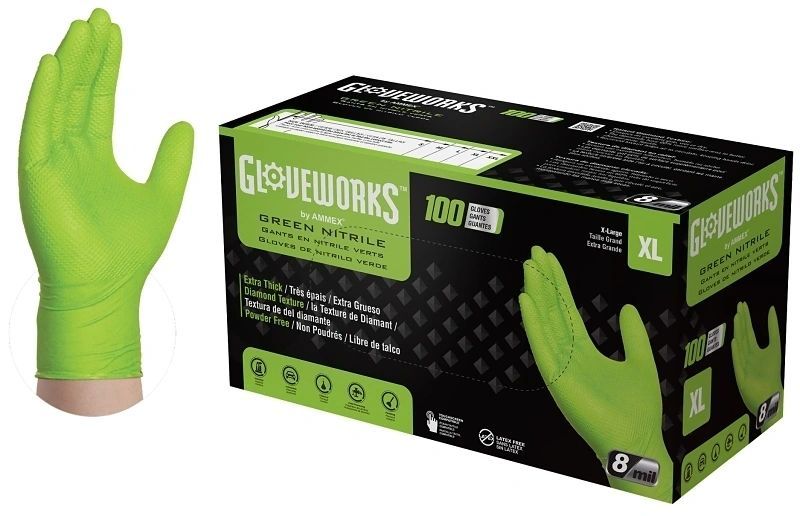

Gloveworks GWGN48100 Heavy-Duty Disposable Gloves, XL, Nitrile, Powder-Free, Green, 9-1/2 in L

Your job is tough you work all day with tools, machinery, harsh chemicals. You need a glove that can stand up to more. AMMEX® Gloveworks® HD green nitrile powder-free industrial gloves stay strong until the job is finished. This is not just another disposable glove. It's truly premium, engineered to deliver superior protection to the pros who need it most. The grip is unbeatable, thanks to its raised diamond texture our most aggressive, with 60% more surface area. Those diamonds channel away liquids, so even when the glove is wet you can still hold on tight and they create a reverse texture on the inside, which helps air to circulate and keep your hands drier. The high-visibility color really demands to be seen. You won't lose sight of your co-workers' hands, nor will they lose sight of yours, a safety bonus. AMMEX® Gloveworks® HD green nitrile powder-free industrial gloves boast an 8 to 9 mil thickness, durable, resistant to punctures, tears and rips, with excellent barrier protection against grease, pesticides, gasoline and a long list of specialty chemicals. They're designed for extended duration use. The gold standard for automotive, manufacturing, janitorial, plumbing, paint shop and industrial uses, they're made from component materials that comply with FDA regulations for food contact, making them perfect for food processing applications. AMMEX® Gloveworks® HD green nitrile powder-free industrial gloves will change the way you work so much that you'll never feel comfortable wearing any other disposable glove.

Color: Green Cuff Type: Beaded

Includes:(100) Disposable Gloves Latex Free: Yes

Length:9-1/2Material:NitrilePowdered/ Powder Free: Powder-Free

Resists: Chemical Puncture Rip Tear

Size:XLThickness:8 mil

Features

- Diamond textured grip

- Chlorinated finish

DIABLO HOLE SAW BI-METAL

DIABLO HOLE SAW 3/4 X 2-3/8 INCH BI-METAL

Ideal for drilling wood, plastic, aluminum, metal and stainless steel. 60mm (2-3/8") cutting depth for deeper holes in one pass and increased productivity. Snap-Lock mandrel system for a quick and easy change with no down time.

Applicable Materials:

Aluminum Metal Plastic Stainless Steel Wood

Arbor Size:

3/8 in

Cutting Depth:

2-3/8 in

Cutting Edge Material:

Bi-Metal

Diameter:

3/4 in

Length:

7.0 in

Pilot Drill Size:

1/4 in Dia x 3-1/2 in L

Shank Type:

Mandrel

Tooth Type:

Variable Pitch

Type:

High Performance

Scripto Lighter Fluid

Lighter Fluid and Solvent

Vulcan JL24116-16W Mallet, 16 oz Head, Double-Faced Head, Rubber Head, 13-1/2 in OAL

Vulcan JL24116-16W Mallet, 16 oz Head, Double-Faced Head, Rubber Head, 13-1/2 in OAL

Mallet hammer with 16 oz, double-faced, rubber head, white color. Wood Handle, 11 in L.

Face Diameter:

2-1/8 in

Handle Color:

Nature

Handle Length:

11 in

Handle Material:

Wood

Handle Type:

Wood Handle

Head Color:

White

Head Length:

3-3/4 in

Head Material:

Rubber

Head Type:

Double-Faced

Head Weight:

16 oz

Head Width:

2-1/8 in

Overall Length:

13-1/2 in

Duke Traps 0510 Raccoon Trap

Coil spring traps are foot-hold restraining devices used to catch and hold wild animals. This style of trap has been in use since the early part of the 20th century and is widely accepted as a cost effective and efficient tool for managing wildlife populations. Coil spring traps are manufactured of steel components and powered by a set of compact coil springs.

Product Details

Finish: Powder-Coated Material: Steel

Features

For raccoon

Parker Hydraulic Industry Standard Hose 2500-5800 PSI – 471 1/4" Hose 471TC-4 (Sold by the Foot)

Parker Hydraulic Industry Standard Hose 2500-5800 PSI – 471 1/4" Hose 471TC-4

Part #: 471TC-4

Parker's 471 hose is a hydraulic industry standard hose that has a pressure range of 2500-5800 PSI, with a synthetic rubber inner tube which provides wide fluid compatibility.

Technical Specifications

Weight:0.30 kg/m, 0.20 lb/ft

Minimum Operating Temperature:-40 °C, -40 °F

Hose Cover Type: Tough Cover

Media: Lubricants, Petroleum Hydraulic Fluids

Specifications Met: ABS, BV, DNV, EN 857, Type 2SC, ISO 11237, Type 2SC, SAE J1942, USCG HF

Compatible Fitting:43 Series

Inside Diameter:1/4 inch, 6.3 mm

Application: Lubricating Oils, Petroleum Base Hydraulic Fluids

Hose Reinforcement Material:2 Braids of Steel Wire

Nominal Hose Inside Diameter:6 mm

Outside Diameter:0.510 inch, 13 mm

Maximum Operating Pressure:5800 psi, 40 MPa

Hose I.D. (size):-4Hose

Inner Tube Material: Synthetic Rubber Cover Material: Synthetic Rubber Abrasion Resistant, MSHA Approved

Minimum Bend Radius:2 inch, 50 mm Vacuum

Pressure Rating:28 Inch-Hg, 95 kPa

Maximum Operating Temperature:212 °F, 100 °C

Safety Notice

WARNING: Products may contain a chemical known to the State of California to cause birth defects, cancer or other reproductive harm. For more information go to www.p65warnings.ca.gov

https://ph.parker.com/us/en/product/hydraulic-industry-standard-hose-5800-2500-psi-471-hose/471tc-4#safetywarning

Item Information

Parker's 471 hose is a hydraulic industry standard hose that has a pressure range of 2500-5800 PSI, with a synthetic rubber inner tube which provides wide fluid compatibility. The 471 hose is designed, built, and tested to meet ISO 11237 Type 2SC, SAE J1942, and EN 857 Type 2SC specifications. The two-wire braided construction offers more flexibility than the standard spiral counterpart in order to fit your needs. Sizes range from ¼” to 1” in diameter with different cover options available for various markets.

Markets:

• Transportation

• Military

• Agriculture

• Forestry

• Utility Equipment

• Waste & Refuse

• Material Handling

• Industrial

Features/Benefits:

• Tough Cover or Super Tough cover options to prevent abrasion

• Half SAE bend radius for ease of installation and low force to flex

• 2500-5800 PSI working pressure in different sizes

• 2-wire braided compact construction offers more flexibility

• Smaller O.D. for ease of installation

Applications:

• Petroleum base hydraulic fluids and lubricating oils

Compatible Fittings:

• 43 series fittings

Parker Hydraulic Industry Standard Hose 2500-5800 PSI – 471 Hose 3/8" Part #: 471TC-6 (Sold by the Foot)

Parker Hydraulic Industry Standard Hose 2500-5800 PSI – 471 Hose 3/8" Part #: 471TC-6

Technical Specifications

Weight:0.28 lb/ft, 0.42 kg/m Minimum Operating Temperature:-40 °C, -40 °F

Hose Cover Type: Tough Cover

Media: Lubricants, Petroleum Hydraulic Fluids

Specifications Met: ABS, BV, DNV, EN 857, Type 2SC, ISO 11237, Type 2SC, SAE J1942, USCG HF

Compatible Fitting:43 Series

Inside Diameter:3/8 inch, 10 mm

Application: Lubricating Oils, Petroleum Base Hydraulic Fluids

Hose Reinforcement Material:2 Braids of Steel Wire

Nominal Hose Inside Diameter:10 mm

Outside Diameter:0.680 inch, 17 mm

Maximum Operating Pressure:5000 psi, 35 MPa

Pressure Rating:28 Inch-Hg, 95 kPa Maximum Operating Temperature:212 °F, 100 °C :2-1/2 inch, 65 mm Vacuum

Pressure Rating:28 Inch-Hg, 95 kPaMaximum Operating Temperature:212 °F, 100 °C

Material: Synthetic Rubber Abrasion Resistant, MSHA Approved

Minimum Bend Radius:2-1/2 inch, 65 mm

Vacuum Pressure Rating:28 Inch-Hg, 95 kPa

Maximum Operating Temperature:212 °F, 100 °C

Safety Notice

WARNING: Products may contain a chemical known to the State of California to cause birth defects, cancer or other reproductive harm. For more information go to www.p65warnings.ca.gov

https://ph.parker.com/us/en/product/hydraulic-industry-standard-hose-5800-2500-psi-471-hose/471tc-6#safetywarning

Item Information

Parker's 471 hose is a hydraulic industry standard hose that has a pressure range of 2500-5800 PSI, with a synthetic rubber inner tube which provides wide fluid compatibility. The 471 hose is designed, built, and tested to meet ISO 11237 Type 2SC, SAE J1942, and EN 857 Type 2SC specifications. The two-wire braided construction offers more flexibility than the standard spiral counterpart in order to fit your needs. Sizes range from ¼” to 1” in diameter with different cover options available for various markets.

Markets:

• Transportation

• Military

• Agriculture

• Forestry

• Utility Equipment

• Waste & Refuse

• Material Handling

• Industrial

Features/Benefits:

• ToughCover or SuperTough cover options to prevent abrasion

• Half SAE bend radius for ease of installation and low force to flex

• 2500-5800 PSI working pressure in different sizes

• 2-wire braided compact construction offers more flexibility

• Smaller O.D. for ease of installation

Applications:

• Petroleum base hydraulic fluids and lubricating oils

Compatible Fittings:

• 43 series fittings

Parker Hydraulic Industry Standard Hose 4250-5000 PSI - 471TC-6-6 3/8" Twin Tough Hose (Sold by the Foot)

Parker Hydraulic Industry Standard Hose 4250-5000 PSI - 471TC-6-6 3/8" Twin Tough Hose

Technical Specifications

Weight:0.56 lb/ft, 0.84 kg/m

Minimum Operating Temperature:-40 °F, -40 °C

Media: Lubricants, Petroleum Hydraulic Fluids

Specifications Met: ABS, BV, DNV, EN 857, Type 2SC, ISO 11237, Type 2SC, SAE J1942, USCG HF

Compatible Fitting:43 Series

Hose Reinforcement Material:2 Braids of Steel Wire

Inside Diameter:3/8 inch, 10 mm

Nominal Hose Inside Diameter:10 mm

Outside Diameter:0.680 inch, 17 mm

Application: Lubricating Oils, Petroleum Base Hydraulic Fluids

Maximum Operating Pressure:5000 psi, 35 MPa

Hose Inner Tube Material: Synthetic Rubber

Hose I.D. (size):-6

Cover Material: Synthetic Rubber Abrasion Resistant, MSHA Approved

Minimum Bend Radius:2-1/2 inch, 65 mm

Maximum Operating Temperature:212 °F, 100 °C

Hose Cover Type: Tough Cover

Safety Notice

WARNING: Products may contain a chemical known to the State of California to cause birth defects, cancer or other reproductive harm. For more information go to www.p65warnings.ca.gov

Safety: https://ph.parker.com/us/en/product/hydraulic-industry-standard-hose-5000-4250-psi-471tc-twin-tough-hose/471tc-6-6#safetywarning

Parker’s 471TC Twin Tough hose working pressure of 4250-5000 PSI, was designed to eliminate the labor and material costs required to manually bundle two separate hoses. This saves valuable time in the field. The 471TC Twin Tough hose is reinforced with two steel braids for durability. Sizes are available in 3/8” or ½” diameters to meet your specific needs.

Markets:

• Construction

• Utility Equipment

• Material Handling

• Industrial

Features/Benefits:

• Two hoses bundled with one cover to save labor and material costs

• ToughCover to prevent abrasion

• Half SAE bend radius for ease of installation and low force to flex

• 2-braided compact construction

Applications:

• Petroleum base hydraulic fluids and lubricating oils

Compatible Fittings:

• 43 series fittings

Parker Hydraulic Industry Standard Hose 2500-5800 PSI – 471 1/2" Hose Part #: 471TC-8

Technical Specifications

Weight:0.52 kg/m, 0.35 lb/ft

Minimum Operating Temperature:-40 °C, -40 °F

Hose Cover Type: Tough Cover

Media: Lubricants, Petroleum Hydraulic Fluids

Specifications Met: ABS, BV, DNV, EN 857, Type 2SC, ISO 11237, Type 2SC, SAE J1942, USCG HF

Compatible Fitting:43 Series

Inside Diameter:1/2 inch, 12.5 mm

Application: Lubricating Oils, Petroleum Base Hydraulic Fluids

Hose Reinforcement Material:2 Braids of Steel Wire

Nominal Hose Inside Diameter:12 mm

Outside Diameter:0.800 inch, 20 mm

Maximum Operating Pressure:4250 psi, 29.7 MPa

Hose Inner Tube Material: Synthetic Rubber

Hose I.D. (size):-8

Cover Material: Synthetic Rubber Abrasion Resistant, MSHA Approved

Minimum Bend Radius:3-1/2 inch, 90 mm

Vacuum Pressure Rating:28 Inch-Hg, 95 kPa

Maximum Operating Temperature:212 °F, 100 °C

Safety Notice

WARNING: Products may contain a chemical known to the State of California to cause birth defects, cancer or other reproductive harm. For more information go to www.p65warnings.ca.gov

Safety: https://ph.parker.com/us/en/product/hydraulic-industry-standard-hose-5000-4250-psi-471tc-twin-tough-hose/471tc-6-6#safetywarning

Item Information

Parker's 471 hose is a hydraulic industry standard hose that has a pressure range of 2500-5800 PSI, with a synthetic rubber inner tube which provides wide fluid compatibility. The 471 hose is designed, built, and tested to meet ISO 11237 Type 2SC, SAE J1942, and EN 857 Type 2SC specifications. The two-wire braided construction offers more flexibility than the standard spiral counterpart in order to fit your needs. Sizes range from ¼” to 1” in diameter with different cover options available for various markets.

Markets:

• Transportation

• Military

• Agriculture

• Forestry

• Utility Equipment

• Waste & Refuse

• Material Handling

• Industrial

Features/Benefits:

• ToughCover or SuperTough cover options to prevent abrasion

• Half SAE bend radius for ease of installation and low force to flex

• 2500-5800 PSI working pressure in different sizes

• 2-wire braided compact construction offers more flexibility

• Smaller O.D. for ease of installation

Applications:

• Petroleum base hydraulic fluids and lubricating oils

Compatible Fittings:

• 43 series fittings

Parker Hydraulic Industry Standard Hose 2500-5800 PSI – 471 1/2" Hose Part #: 471TC-8

Technical Specifications

Weight:0.52 kg/m, 0.35 lb/ft

Minimum Operating Temperature:-40 °C, -40 °F

Hose Cover Type: Tough Cover

Media: Lubricants, Petroleum Hydraulic Fluids

Specifications Met: ABS, BV, DNV, EN 857, Type 2SC, ISO 11237, Type 2SC, SAE J1942, USCG HF

Compatible Fitting:43 Series

Inside Diameter:1/2 inch, 12.5 mm

Application: Lubricating Oils, Petroleum Base Hydraulic Fluids

Hose Reinforcement Material:2 Braids of Steel Wire

Nominal Hose Inside Diameter:12 mm

Outside Diameter:0.800 inch, 20 mm

Maximum Operating Pressure:4250 psi, 29.7 MPa

Hose Inner Tube Material: Synthetic Rubber

Hose I.D. (size):-8

Cover Material: Synthetic Rubber Abrasion Resistant, MSHA Approved

Minimum Bend Radius:3-1/2 inch, 90 mm

Vacuum Pressure Rating:28 Inch-Hg, 95 kPa

Maximum Operating Temperature:212 °F, 100 °C

Safety Notice

WARNING: Products may contain a chemical known to the State of California to cause birth defects, cancer or other reproductive harm. For more information go to www.p65warnings.ca.gov

Safety: https://ph.parker.com/us/en/product/hydraulic-industry-standard-hose-5000-4250-psi-471tc-twin-tough-hose/471tc-6-6#safetywarning

Item Information

Parker's 471 hose is a hydraulic industry standard hose that has a pressure range of 2500-5800 PSI, with a synthetic rubber inner tube which provides wide fluid compatibility. The 471 hose is designed, built, and tested to meet ISO 11237 Type 2SC, SAE J1942, and EN 857 Type 2SC specifications. The two-wire braided construction offers more flexibility than the standard spiral counterpart in order to fit your needs. Sizes range from ¼” to 1” in diameter with different cover options available for various markets.

Markets:

• Transportation

• Military

• Agriculture

• Forestry

• Utility Equipment

• Waste & Refuse

• Material Handling

• Industrial

Features/Benefits:

• ToughCover or SuperTough cover options to prevent abrasion

• Half SAE bend radius for ease of installation and low force to flex

• 2500-5800 PSI working pressure in different sizes

• 2-wire braided compact construction offers more flexibility

• Smaller O.D. for ease of installation

Applications:

• Petroleum base hydraulic fluids and lubricating oils

Compatible Fittings:

• 43 series fittings

Parker 5/8" 471TC-10 - Hydraulic Industry Standard Hose 2500-5800 PSI

Description:

5/8" Medium pressure tough cover hydraulic hose for use with petroleum base hydraulic fluids and lubricating oils. Inner Tube: Synthetic rubber. Reinforcement: Two braids steel wire. Cover: Synthetic rubber abrasion resistant, MSHA accepted.

Product Attributes

Inner Diameter:0.625 Inch

Working Pressure:3625 PSI (250 bar)

Material: Rubber

UOM:FT

Hose Category: Hydraulic Industry Standard

Application: Hydraulic

Series:471TC

Hose Pressure Range: Medium

Inch/Metric: Inch

Distinct Properties: Tough Cover

Working Pressure Range: 3000 to 3999 PSI (207 to 276 bar)

Inner Diameter Inch/mm: Inch

Parker Division :Hose Products

Parker Group: Fluid Connector

Specification: ISO 11237-1 TYPE 2SC / EN 857 TYPE 2SC

Application: Hydraulic

Specific Application: Petroleum base hydraulic fluids and lubricating oils

Distinct Properties: Tough Cover

Safety Notice

WARNING: Products may contain a chemical known to the State of California to cause birth defects, cancer or other reproductive harm. For more information go to www.p65warnings.ca.gov

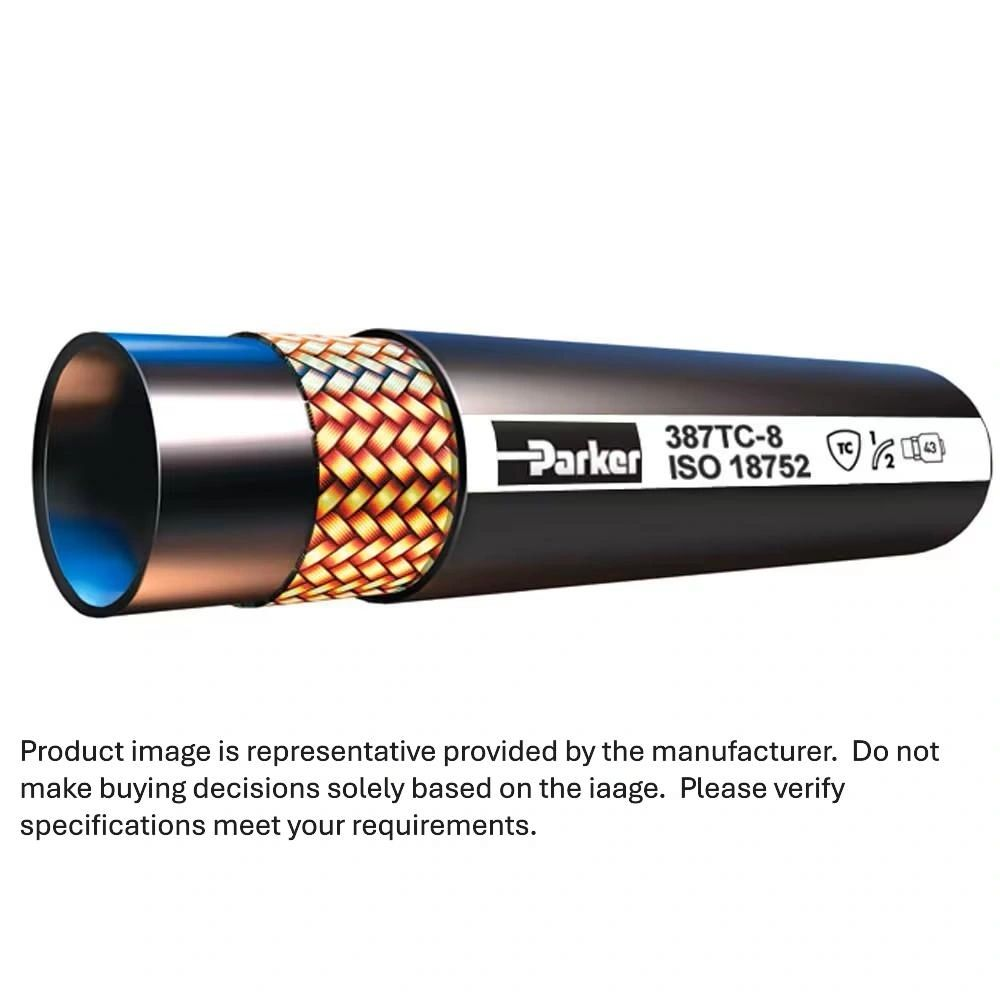

Parker Hydraulic Constant Working Pressure Hose 3000 PSI - Global Core 387 Hose 1" Part #: 387TC-16

Part of Parker’s Global Core constant working pressure hose line, lightweight and flexible 387 hoses consistently deliver 3,000 PSI performance across markets and across the globe.

Technical Specifications

Weight:0.79 lb/ft, 1.17 kg/m

Disclaimer: The user, through its own analysis and testing, is solely responsible for making the final selection of the system and components and assuring that all performance, endurance, maintenance, safety and warning requirements of the application are met.

Minimum Operating Temperature:-40 °F, -40 °C

Minimum Bend Radius:150 mm, 6 inch

Hose I.D. (size):-16

Media: Lubricants, Petroleum Hydraulic Fluids

Specifications Met: ISO 18752, Type AC, MSHA TC & ST covers only

Application: Lubricating Oils, Petroleum Base Hydraulic Fluids

Hose Reinforcement Material:2 Braids of Steel Wire

Compatible Fitting:43 Series

Nominal Hose Inside Diameter:25 mm

Inside Diameter:1 inch, 25 mm

Outside Diameter:1.4 inch, 35.4 mm

Maximum Operating Pressure:3000 psi, 21 MPa, 210 bar

Hose Inner Tube Material: Synthetic Rubber

Cover Material: Synthetic Rubber Abrasion Resistant

Maximum Operating Temperature:257 °F, 125 °C

Hose Cover Type: Tough Cover

Size:-16

Hose Cover Type: Tough Cover

Safety Notice

WARNING: Products may contain a chemical known to the State of California to cause birth defects, cancer or other reproductive harm. For more information go to www.p65warnings.ca.gov

The Parker 387 Global Core hose is a constant working pressure hydraulic hose offering 3,000 PSI in all sizes. This light, durable, and easy-to-bend hose meets and exceeds ISO 18752 performance specifications. The 387 hose offers low force-to-flex and delivers full SAE-standard pressure at one-half SAE bend radius, resulting in easier handling and installation. 387 hose also offers a 30% smaller OD by area compared with SAE-standard spiral hose. Compatible with petroleum-based hydraulic fluids and lubricating oils, 387 Global Core hose is offered in sizes ranging from ¼-inch to 2 inches in diameter and with three cover options: Standard, Tough Cover, and Super Tough.

Markets:

• Transportation

• Military

• Construction

• Agriculture

• Grounds & Building Maintenance

• Waste & Refuse

• Material Handling

• Forestry

• Railroad

• Utility Equipment

• Personal Lift Equipment

• Machine Tool

Features/Benefits:

• Standard or Tough Cover options to prevent abrasion

• Half SAE bend radius for ease of installation and low force to flex

• 30% smaller O.D. by area compared to the SAE spiral hose

• 3,000 PSI constant working pressure in all sizes

• Lighter than the standard SAE spiral hose

Applications:

• Petroleum base hydraulic fluids and lubricating oils

Compatible Fittings:

• 43 series fittings (for sizes -4 to -20)

• 77 series fittings (for sizes -20 to -32)

Parker Hydraulic Constant Working Pressure Hose 3000 PSI - Global Core 387 Hose 1-1/4" Part #: 387TC-20

Part of Parker’s Global Core constant working pressure hose line, lightweight and flexible 387 hoses consistently deliver 3,000 PSI performance across markets and across the globe.

Technical Specifications

Weight:1.74 lb/ft, 2.59 kg/m

Disclaimer: The user, through its own analysis and testing, is solely responsible for making the final selection of the system and components and assuring that all performance, endurance, maintenance, safety and warning requirements of the application are met.

Minimum Operating Temperature:-40 °C, -40 °F

Minimum Bend Radius:210 mm, 8-1/4 inch

Hose I.D. (size):-20Media:Lubricants, Petroleum Hydraulic Fluids

Specifications Met: ISO 18752, Type CC, MSHA TC & ST covers only

Application: Lubricating Oils, Petroleum Base Hydraulic Fluids

Hose Reinforcement Material:4 Spirals

Compatible Fitting: 43 Series, 77 Series

Nominal Hose Inside Diameter: 31 mm

Inside Diameter: 1-1/4 inch, 31.5 mm

Outside Diameter: 1.820 inch, 46.3 mm

Maximum Operating Pressure: 3000 psi, 21 MPa, 210 bar

Hose Inner Tube Material: Synthetic Rubber

Cover Material: Synthetic Rubber Abrasion Resistant

Maximum Operating Temperature: 257 °F, 125 °C

Hose Cover Type: Tough Cover

Size: 20

Hose Cover Type: Tough Cover

Safety Notice

WARNING: Products may contain a chemical known to the State of California to cause birth defects, cancer or other reproductive harm. For more information go to www.p65warnings.ca.gov

Item Information:

The Parker 387 Global Core hose is a constant working pressure hydraulic hose offering 3,000 PSI in all sizes. This light, durable, and easy-to-bend hose meets and exceeds ISO 18752 performance specifications. The 387 hose offers low force-to-flex and delivers full SAE-standard pressure at one-half SAE bend radius, resulting in easier handling and installation. 387 hose also offers a 30% smaller OD by area compared with SAE-standard spiral hose. Compatible with petroleum-based hydraulic fluids and lubricating oils, 387 Global Core hose is offered in sizes ranging from ¼-inch to 2 inches in diameter and with three cover options: Standard, Tough Cover, and Super Tough.

Markets:

• Transportation

• Military

• Construction

• Agriculture

• Grounds & Building Maintenance

• Waste & Refuse

• Material Handling

• Forestry

• Railroad

• Utility Equipment

• Personal Lift Equipment

• Machine Tool

Features/Benefits:

• Standard or Tough Cover options to prevent abrasion

• Half SAE bend radius for ease of installation and low force to flex

• 30% smaller O.D. by area compared to the SAE spiral hose

• 3,000 PSI constant working pressure in all sizes

• Lighter than the standard SAE spiral hose

Applications:

• Petroleum base hydraulic fluids and lubricating oils

Compatible Fittings:

• 43 series fittings (for sizes -4 to -20)

• 77 series fittings (for sizes -20 to -32)

Parker Hydraulic Constant Working Pressure Hose 3000 PSI - Global Core 387 Hose 1-1/2" Part #: 387TC-24

Sold by the Foot

Part of Parker’s Global Core constant working pressure hose line, lightweight and flexible 387 hoses consistently deliver 3,000 PSI performance across markets and across the globe.

Inside Di

Technical Specifications

Weight:2.99 kg/m, 2.01 lb/ft

Disclaimer: The user, through its own analysis and testing, is solely responsible for making the final selection of the system and components and assuring that all performance, endurance, maintenance, safety and warning requirements of the application are met.

Minimum Operating Temperature:-40 °F, -40 °C

Minimum Bend Radius:250 mm, 10 inch

Hose I.D. (size):-24Media:Lubricants, Petroleum Hydraulic Fluids

Specifications Met: ISO 18752, Type CC, MSHA TC & ST covers only

Hose Reinforcement Material:4 Spirals

Compatible Fitting: 77 Series

Application: Lubricating Oils, Petroleum Base Hydraulic Fluids

Diameter:1-1/2 inch, 38 mm

Nominal Hose Inside Diameter:38 mm

Outside Diameter:2.080 inch, 52.8 mm

Maximum Operating Pressure:3000 psi, 21 MPa, 210 bar

Hose Inner Tube Material: Synthetic Rubber Cover

Material: Synthetic Rubber Abrasion Resistant

Maximum Operating Temperature:257 °F, 125 °C

Hose Cover Type: Tough Cover Size: 24

Hose Cover Type: Tough Cover

Safety Notice

WARNING: Products may contain a chemical known to the State of California to cause birth defects, cancer or other reproductive harm. For more information go to www.p65warnings.ca.gov

Safety Notice:

For more information go to

https://www.parker.com/us/en/safety.html#:~:text=Safety-,Safety,Sporlan%20Division%20Safety%20Guide,-Americas

The Parker 387 Global Core hose is a constant working pressure hydraulic hose offering 3,000 PSI in all sizes. This light, durable, and easy-to-bend hose meets and exceeds ISO 18752 performance specifications. The 387 hose offers low force-to-flex and delivers full SAE-standard pressure at one-half SAE bend radius, resulting in easier handling and installation. 387 hose also offers a 30% smaller OD by area compared with SAE-standard spiral hose. Compatible with petroleum-based hydraulic fluids and lubricating oils, 387 Global Core hose is offered in sizes ranging from ¼-inch to 2 inches in diameter and with three cover options: Standard, Tough Cover, and Super Tough.

Markets:

• Transportation

• Military

• Construction

• Agriculture

• Grounds & Building Maintenance

• Waste & Refuse

• Material Handling

• Forestry

• Railroad

• Utility Equipment

• Personal Lift Equipment

• Machine Tool

Features/Benefits:

• Standard or Tough Cover options to prevent abrasion

• Half SAE bend radius for ease of installation and low force to flex

• 30% smaller O.D. by area compared to the SAE spiral hose

• 3,000 PSI constant working pressure in all sizes

• Lighter than the standard SAE spiral hose

Applications:

• Petroleum base hydraulic fluids and lubricating oils

Compatible Fittings:

• 43 series fittings (for sizes -4 to -20)

• 77 series fittings (for sizes -20 to -32)

ParkerHydraulic Industry Standard Hose 575-3250 PSI – 422 Hose 2" - 422-32

Sold by the foot